Progressive cavity pumps (PCPs) are workhorses across a wide range of industries, from wastewater treatment and oil and gas to food processing and chemical manufacturing. Their ability to handle viscous, abrasive, and even shear-sensitive fluids makes them a go-to solution when centrifugal or diaphragm pumps fall short.

Despite their versatility and efficiency, PCPs are not immune to breakdowns. In fact, their unique design — involving a helical rotor turning within a resilient stator — makes them susceptible to specific

failure modes. When a PCP fails, the impact can be significant: unexpected downtime, lost production, costly repairs, and safety concerns. For industrial engineers and operations managers, understanding why these failures occur and how to prevent them is key to long-term reliability.

Common Progressive Cavity Pump Performance Problems

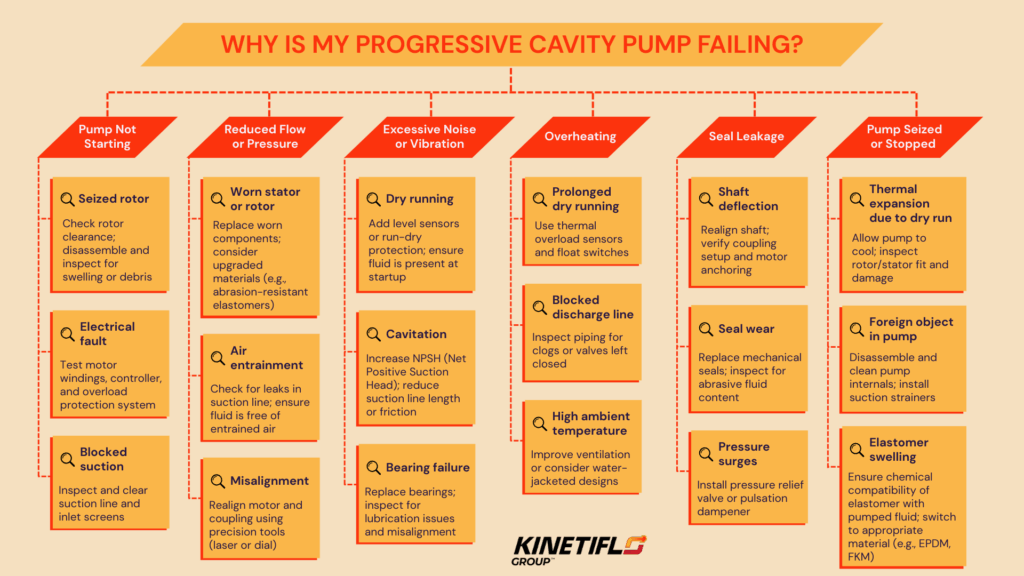

Progressive cavity pumps exhibit several failure symptoms that often serve as red flags for deeper systemic issues:

Each of these symptoms reduces operational efficiency and points to underlying issues that, if ignored, may lead to catastrophic pump failure.

Root Causes Breakdown

Understanding root causes is essential to applying targeted fixes and developing preventive measures. Here are the most common culprits:

PCPs must be properly matched to the fluid they are pumping. Incompatible materials (e.g., using a nitrile stator with aggressive solvents) degrade quickly, leading to stator swelling, delamination, and eventual pump failure. Elastomer selection is critical, especially in chemical and food-grade applications.

A frequent and costly mistake, dry running occurs when a pump operates without sufficient fluid in the stator cavity. This creates heat from friction between the rotor and stator, leading to rapid wear, elastomer degradation, and eventual seizure. Many operators neglect to prime the pump or check for fluid presence before startup, particularly in automated systems.

PCPs require precise alignment between the motor and pump shaft. Misalignment causes uneven wear on bearings and seals, leading to vibration, leakage, and eventually rotor damage. Moreover, infrequent or improper maintenance, such as ignoring seal replacement schedules or operating with worn stators, compounds wear and reduces efficiency.

Solutions and Fixes

To mitigate common failures, a combination of best practices and engineering controls must be implemented.

Preventive maintenance is one of the most effective strategies for PCP longevity. Create a checklist that includes:

A preventive maintenance program should be tailored to the operating conditions and fluid characteristics.

Proper installation minimizes stress on components and ensures reliable performance. Key tips include:

Even a slight deviation in alignment can significantly reduce mechanical seal life and bearing integrity.

When facing repeated failures due to wear or corrosion, upgrading materials can pay dividends:

Material upgrades should always be reviewed in light of fluid characteristics, temperature, and expected duty cycles.

Prevention: Designing Out Failure

Proactive design and system integration are key to reducing PCP failure rates. Consider the following strategies:

Instead of sizing the pump after piping and tank layouts, reverse the process:

Real-time monitoring tools can detect early signs of failure:

These tools, combined with PLC alerts or SCADA systems, enable predictive maintenance and quick intervention.

Many failures result from human error. Regular training and clear standard operating procedures (SOPs) help operators understand:

Clear documentation and signage near control panels reinforce best practices.

Why Working With Experts & Eliminating Costly Failures Pays Off

Progressive cavity pump failures can be frustrating and expensive, but they are far from inevitable. By identifying common failure symptoms, tracing their root causes, and applying targeted fixes, industrial operations can dramatically increase uptime, reduce maintenance costs, and extend the life of their equipment.

Better still, designing systems with the pump in mind — and integrating real-time monitoring and strong maintenance protocols — makes failure prevention part of everyday operations. Investing in reliability engineering today means fewer surprises tomorrow.

Need help troubleshooting or upgrading your pumping systems? Contact Kinetiflo to speak with a PCP expert and learn how we can help you reduce failures and improve operational efficiency.